User Tools

This section of the Alphatross project folder is to store all work related to the Alphatross temperature control upgrade.

The current work is to replace out hack job heater with a more robust and reliable system. The planned major system components are

Bosch Tronic mini-tank water heater: https://www.lowes.com/pd/Bosch-Tronic-Mini-Tank-7-Gallon-Lowboy-6-year-Limited-1440-watt-1-Element-Point-of-Use-Electric-Water-Heater/5000622217

March AC-4C-MD Magnetically Coupled Pump: https://www.marchpump.com/pump/ac-4c-md-magnetically-coupled-pump/

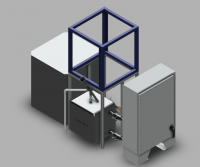

The 3D CAD models are mostly done in Fusion 360, and can be viewed online at: https://a360.co/33Lxe0K

We plan to use schedule 40 3/4“ PVC piping for most of the connections. This material is cheap, easily available, and chemically resistant. It it also rated for temperatures of 140°F (60°C). Our target working temperature is 40°C, giving us a pressure derating factor of 50%. This gives a maximum working pressure of 145 PSI (135 PSI for 1”) well in excess of anything we expect to generate.

Plumbing was designed for long-term use and ease of maintenance. Union-type valves were selected with NPT threaded fittings. This allows us to replace the cheap and readily available PVC to socket adapters, rather than needing to stock spares of special and expensive valve sockets.

The port at the top of the tank will be retrofitted with a T to allow installation of a clear PVC pipe to act as a sight glass, along with a valve and a fill port, for adding oil to the system. A temperature and pressure relief valve will also be installed on this port (valve is supplied with the water heater).

A drip-pan will be installed below the entire system, to contain any oil in the event of a plumbing break or relief valve event.

The existing 19“ rack will be replaced with some 19” square-hole rack rail mounted to an 80-20 frame. This 80-20 frame will also support the water heater and piping.