User Tools

Alpha Source Instructions

Duoplasmatron Instructions

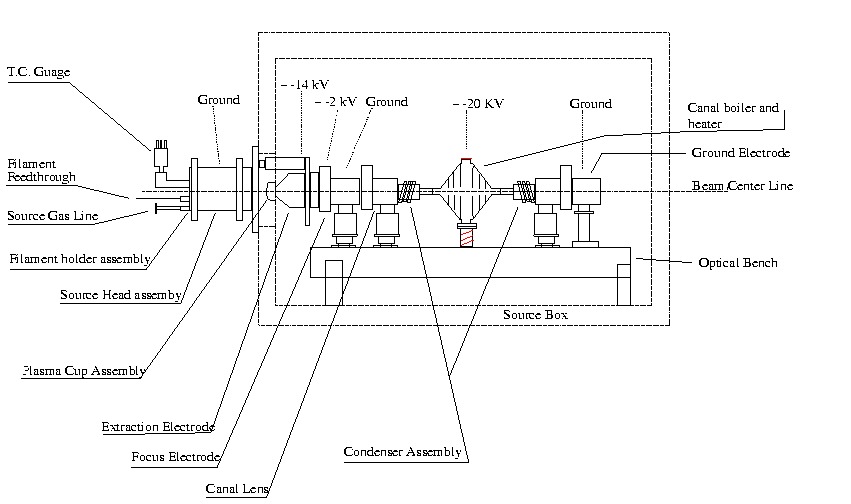

Please study the diagram below.

These instructions were developed by David Ingram, please e-mail any comments or questions about them to him, at ingram@ohio.edu.

This page includes: Duoplasmatron cold start, warm start, start from standby; shutdown completely, shutdown for warm start, shutdown to standby; Trouble shooting; 3He operation.

Duoplasmatron Start-up

You need to determine what the state of the source is before you do anything. Depending on the electrical and vacuum status the source will be starting from cold, warm, or standby.

The first check you need to make is on the vacuum status of the source. The source pressure should be less than 5×10-6 torr. If it is not find out why before going any further.

If the control power for the machine, and/or for the source are off, or if the sodium canal supply is off or at zero current, you are starting from the cold state.

If the power to the source console is on and the sodium canal heater current is ~0.3 A and a beam has been successfully extracted previously, then the source is starting already warm.

If the power to the source console is on and the sodium canal heater current is ~0.55 A and there is ~0.75 A of arc and the extraction and canal supplies are on, then the source is in standby.

If the source is in any other state please ask before proceeding.

Starting warm

This applies when the source already been run successfully and the Sodium heater current left at ~0.3 A, and is the usual state from which to start the source. At the Control Console:

1. Check the source vacuum is less than 5×10-6 torr.

In the Vault:

1. Check the vacuum in the low energy extension is less than 5×10-6 torr then open the tube gate valve on the ion source vacuum control panel.

2. Check valve on gas supply bottle is open and regulator set for ~5 psig. Note this will be the case unless work has been done on the gas supply systems, the supply bottle is very low (causing the regulator to read high), or you are changing between 4He and 3He. See instructions below on running 3He. If is suspected that there is air or another contaminant in the gas lines then they should be roughed out and purged three times using the roughing pump on the leak checker.

On the way back to the control room:

1. Adjust buncher tubes, slit settings, and open HE and LE gate valves.

Back at the Control Console:

1. Turn source magnet up to ~0.2 A. (likely already set, and it can be as high as 1.4 A)

2. Turn up the source gas until the pressure on the source tc gauge is ~300 microns (sometimes higher pressures are needed to start the source, but the source will run as low as 150 microns and the lower the pressure the better the quality of the beam and the less gas is used: a consideration when running 3He).

3. Set the Arc Voltage to ~190 V.

4. Turn on the extraction supply, it should be set for 10-12 kV. This will also bring up exchange canal power supply to about 13 kV.

5. Turn on the focus supply, it should be set for ~2 kV.

6. Turn up the sodium heater current to 0.55 A.

7. Slowly turn up the Filament Current to 40-50 A and wait 5 minutes. Continue to raise the Filament Current until the arc starts, 60 A for an old filament, 70 a for a new filament, observe the Arc Voltage and keep it at 150 V.

8. Carry on increasing the filament current until the arc current reaches 2.5 A, keep the Arc Voltage at 150 V.

9. Increase the sodium heater current until it reaches up to 0.6 A, or whatever was used the last time the source was run – check the log.

10. Set the inflection magnet to about 0.8 amps and LEFT deflection.

11. To obtain the maximum current adjust the following:

- Focus

- Inflection Magnet

- Einzel lenses A and B

- X and Y steerers

12. Typical Settings:

- Extraction : 12 kV @ < 1 mA

- Exchange Canal: 13 kV @ 1 mA

- Focus: 2 kV @ 1.5 mA

- Magnet : 0.2 - 1.4A

- Heater: 0.58 A

- Arc Voltage: 150 V

- Filament Current: 70 - 90 amps

- Arc Current: 2.5 amps

- Source lens: 2 kV

- Lens A: <5 kV

- Lens B: <5 kV

- 2Y: 5.00

- 2X: 5.00

- Box Vacuum: 2.0x10E-6 torr

Starting from cold

This applies when the source had been at atmosphere for any reason, including cleaning, sodium refill, or filament replacement. It also applies if the sodium canal heater has been off or at zero current for more than one day.

At the Control Console:

1. Turn on main control power key (if it is off).

2. Turn on source control power key at the source (if it is off).

3. Check the source vacuum is less than 5×10-6 torr.

4. Make sure the voltage is turned down on EINZEL LENS B.

In the Vault:

1. Check the vacuum in the low energy extension is less than 5×10-6 torr then open the tube gate valve on the ion source vacuum control panel.

2. Check valve on gas supply bottle is open and regulator set for ~5 psig. Note this will be the case unless work has been done on the gas supply systems, the supply bottle is very low (causing the regulator to read high), or you are changing between 4He and 3He. See instructions below on running 3He. If it is suspected that there is air or another contaminant in the gas lines then they should be roughed out and purged three times using the roughing pump attached to the helium manifold.

On the way back to the control room:

2. Adjust buncher tubes, slit settings, and open HE and LE gate valves.

Back at the Control Console:

1. Increase the sodium heater current slowly, over 30 seconds, to 0.3 A.

2. Observe the source pressure, it will probably rise especially if the sodium has just been changed. Wait twenty minutes, if the pressure after this time is greater than 1×10-5 torr (10×10-6 torr) do not proceed further until it has fallen below this value.

3. Turn source magnet up to ~0.2 A. (likely already set, and it can be as high as 1.4 A)

4. Turn up the source gas until the pressure on the source tc gauge is ~300 microns.

5. Slowly, over 30 seconds, run up the filament current to ~40 amps. Wait twenty minutes, if the pressure after this time is greater than 1×10-5 torr (10×10-6 torr) do not proceed further until it has fallen below this value.

6. Set the arc voltage to ~190 V.

7. Turn on the extraction supply, it should be set for 10-12 kV. This will also turn on the exchange canal power supply, usually set at 13 to 16 kV.

8. Turn on the focus supply, it should be set for ~2 kV.

9. If the exchange canal power supply did not come on with the extractor, check the toggle switch at the lower, right corner of the supply to make sure its on.

10. Increase the sodium heater current by ~0.05 A and the filament current by ~10 A every twenty minutes. Make sure the pressure does not rise over 1×10-5 torr, if it does, do not proceed further until it has fallen below this value.

11. Slowly turn up the Filament Current until the arc starts. When the arc starts, 60 A for an old filament, 70 a for a new filament, observe the Arc Voltage and keep it at 150 V.

12. Carry on increasing the filament current until the arc current reaches 2.5 A, keep the arc voltage at 150 V.

13. Increase the heater current in 0.05 A steps until it reaches 0.57 A.

14. Set inflection magnet to ~0.8 amps and LEFT deflection.

15. Tune for beam in the LE cup by adjusting inflection magnet, source Einzel lens ( EINZEL LENS B), the low energy extension Einzel lens (EINZEL LENS A), and the 2Y, 2X steerers. It may take two hours before even one nanoamp of current is detectable, especially for freshly cleaned sodium canal

16. To obtain the maximum current adjust the following:

- Focus

- Inflection Magnet

- Einzel lenses A and B

- X and Y steerers

17. Typical Settings:

- Extraction : 12 kV @ < 1 mA

- Exchange Canal: 13 kV @ 1 mA

- Focus: 2 kV @ 1.5 mA

- Magnet : 0.2 - 1.4A

- Heater: 0.58 A

- Arc Voltage: 150 V

- Filament Current: 70 - 90 amps

- Arc Current: 2.5 amps

- Source lens: 2 kV

- Lens A: <5 kV

- Lens B: <5 kV

- 2Y: 5.00

- 2X: 5.00

- Box Vacuum: 2.0x10E-6 torr

Starting from standby

This applies when the source has been running but is not being used but is expected to be used within a few hours:

1. Typical Settings:

- Extraction : 12 kV @ < 1 mA

- Exchange Canal: 13 kV @ 1 mA

- Focus: 2 kV @ 1.5 mA

- Magnet : 0.2 - 1.4A

- Heater: 0.55 A

- Arc Voltage: 150 V

- Filament Current: 70 - 90 amps

- Arc Current: 2.5 amps

- Source lens: 2 kV

- Lens A: <5 kV

- Lens B: <5 kV

- 2Y: 5.00

- 2X: 5.00

- Box Vacuum: 2.0x10E-6 torr

At the Control Console:

1. Check the source vacuum is less than 5×10-6 torr.

In the Vault:

1. Check the vacuum in the low energy extension is less than 5×10-6 torr and the source gate valve is open.

On the way back to the control room:

3. Adjust buncher tubes, slit settings, and open HE and LE gate valves.

Back at the Control Console:

1. Increase the filament current until the arc current reaches 2.5 A, keep the Arc Voltage at 150 V.

2. Increase the sodium heater current until it reaches up to 0.6 A, or whatever was used the last time the source was run – check the log.

3. Set the inflection magnet to 0.8 amps and LEFT deflection.

4. To obtain the maximum current adjust the following:

- Focus

- Inflection Magnet

- Einzel lenses A and B

- X and Y steerers

5. Typical Settings:

- Extraction : 12 kV @ < 1 mA

- Exchange Canal: 13 kV @ 1 mA

- Focus: 2 kV @ 1.5 mA

- Magnet : 0.2 - 1.4A

- Heater: 0.58 A

- Arc Voltage: 150 V

- Filament Current: 70 - 90 amps

- Arc Current: 2.5 amps

- Source lens: 2 kV

- Lens A: <5 kV

- Lens B: <5 kV

- 2Y: 5.00

- 2X: 5.00

- Box Vacuum: 2.0x10E-6 torr

Duoplasmatron Warm Shutdown Procedure

This is the standard configuration when finished with the source for an extended amount of time.

1. Turn the sodium heater current down to ~0.3 A.

2. Slowly, over 30 seconds, turn down the filament current and the Arc Voltage to zero.

3. Turn off the extraction supply, the focus supply, and the sodium canal supply (should go off with extractor).

4. Turn off the deflection supplies and run lenses down to zero.

5. If the source will be used again within 24 hours leave the gas set at 300 microns. Otherwise, turn down the source gas until the pressure on the source tc gauge is ~10 microns. The pressure response is delayed, be patient. Do not over-drive the source gas control as it could damage the leak valve.

Duoplasmatron Shut Down Completely

Required in preparation for maintenance. At the control console:

1. Put in the LE cup.

2. Turn Sodium heater down to zero and switch off.

3. Slowly, over 30 seconds, turn down the filament current and the Arc voltage to zero.

4. Turn off the extraction supply, the focus supply, and the sodium canal supply (should go off with extractor). Turn down magnet to zero.

5. Turn off the deflection supplies and run lenses down to zero.

6. Turn down the source gas until the pressure on the source tc gauge is ~10 microns. The pressure response is delayed, be patient. Do not over-drive the source gas control as it could damage the leak valve.

7. After 10 minutes to allow cooling water to circulate, turn control power key off on source control panel.

In the vault:

1. Close “TUBE” gate valve

Duoplasmatron Standby Settings

Use this configuration if the source will be used again in the next few hours.

1. Turn the heater to 0.55 ampere.

2. All High Voltage are left ON.

3. Arc current reduced to ~1 A by reducing filament current and Arc Voltage.

3He operation

This assumes the source is running on 4He already and that the regulator on the 4He bottle is set for no more than 5 psig.

Turn the Filament Current and Arc Voltage to zero

Turn down the source gas until the pressure on the source tc gauge is ~10 microns. The pressure response is delayed, be patient. Do not over-drive the source gas control as it could damage the leak valve.

Go out to the vault and make sure a 3He bottle is ready for use. It MUST have its main valve closed at this point.

Shut off the manifold valve near the floor that is connected to the 4He.

Start the roughing pump that is attached to the manifold and open the manifold valve leading to the pump.

Open the manifold valve to the 3He regulator, also open the valve on the regulator output.

Rough for a minute until the TC gauge on the pump is about 10 microns.

Close the manifold valve to the rough pump and turn off the pump.

Open the 3He bottle main valve, regulator should go to ~ 5 psig. Record the bottle pressure on the tag.

At the control console, turn up the source gas until the pressure on the source tc gauge is ~300 microns. Flip the tag on the panel around to show 3He.

Reverse this procedure to return to 4He operation, except don’t rough beyond the 4He manifold valve (don’t rough line and regulator) when you have finished using 3He.

Trouble Shooting the Duoplasmatron Source

This is a list of common problems. Please add your own experiences to this page.

Major Symptoms: No beam current

- If there is no arc current, check for filament current, if not, the filament is burned out.

- No Arc voltage; check circuit breaker CB-01 on power supply in source power supply cabinet in vault. This breaker will go out if arc current exceeds 3 amps.

- Check Probe Bias, if this is almost the same (90%) as the Arc Voltage, then filament is probably shorted to plasma cup and needs cleaning.

Little or decreasing beam current

- Sodium in heater is running out.

- Sodium canal plugged up, needs to be cleaned

- Filament current low, <65 A, replace filament.

- Einzel lens power supplies – check circuit breakers ( see circuit breaker list).

- Inflection magnet is out of adjustment.

- Poor vacuum.

Original Credits

Maintained by: Thomas N. Massey Office: Accelerator Lab 217 Telephone: (740)593-0933 E-Mail: MASSEY@OHIOU.EDU Last modified on 3/16/2012 TNM